Welcome to the future! Watch the video of our Open House!

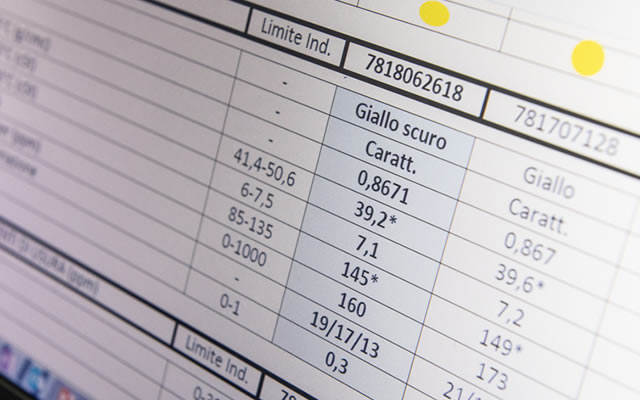

Preventive tribological

oil analysis

By establishing the specific conditions of the lubrication fluid, we are able to determine the state of health of your system and promptly manage the hydraulic circuits to prevent and avoid failures, interruptions and malfunctions.

Filtration and flushing of industrial lubricants

Cleaning industrial lubrication oils is essential for the proper operation of industrial machinery. The flushing for the breaking-in of a new system and the periodic filtration of the oils guarantee efficiency, functionality and efficiency to your business.

Lubrication management plans for industrial systems

Your company no longer has to worry about unplanned downtime or delays caused by plant malfunctions. Professional lubrication management enables you to increase your productivity and improve efficiency.

We have the numbers to support your business

Learn how to increase your company’s performance

through lubricant analysis, programming and management

With the proper management of industrial oils, it is possible to drastically reduce downtimes, breakdowns and unplanned production stoppages: in other words, it is possible to reduce the costs and incidence of damage of these malfunctions.

Our mission is to provide industrial activities with specialised, professional and highly experienced support that can lower costs and increase productivity while respecting the surrounding environment.

Predictive analyses

The productivity check-up for your business

Predictive tribological analyses allow us to know the exact condition of the oils in use and, thus, to accurately assess the overall “state of health” of the plant. With a simple sampling of the lubricant, we are able to plan the oil filtration operations well in advance, avoiding long, unplanned and costly machine downtimes, breakdowns and breakages.

Oil filtration

Plan your oil management

With our oil filtration service, the risk of unexpected breakdowns and emergency repairs is significantly reduced, resulting in improved efficiency, increased productivity and reduced extra costs for drastic and urgent repairs for the industrial plant. Professional lubricant filtration planning operations means taking care of the machinery to ensure optimal operating conditions at all times.

NO DOWNTIME

Forget about sudden shutdowns of your systems! With proper oil management you will always know the condition of your machinery.

LOWER YOUR COSTS

Exceptional repairs, machine stoppages and breakdowns have a major impact on the costs of any business. With proper lubricant filtration scheduling, you can significantly reduce malfunctions and additional costs.

RESPECTING THE ENVIRONMENT

Correct management of the lubrication fluids allows the life of the oil to be extended by 4-5 times and drastically reduces the quantity purchased, disposed of and managed: a clear economic advantage that also brings important benefits for the environment.

Lo sport è passione, impegno e lavoro di squadra. Valori che condividiamo anche nella nostra azienda.

Orgogliosi di sponsorizzare il torneo da calcio di Polpenazze! ⚽💪

#Sponsor #Polpenazze #ValoreDelloSport #Impegno #LavoroDiSquadra ... See MoreSee Less

Comment on Facebook

La manutenzione è la chiave che tiene ogni azienda in movimento.

Ogni macchina che funziona alla perfezione, ogni sistema che non si ferma mai... Tutto questo è possibile grazie alla manutenzione! 💪

In foto uno dei sistemi filtranti di Gatti Filtrazioni Lubrificanti in azione. Sei curioso di scoprire da vicino tutte le nostre soluzioni di manutenzione predittiva?

Il 16-18 settembre 2024, PalaCongressi di Rimini. Ti aspettiamo!

@EuroMainetence24 ... See MoreSee Less

Comment on Facebook

Spettrometro a emissione ottica. Sei curioso di sapere a cosa serve?

È uno strumento in grado di rilevare la presenza di determinate sostanze all’interno dei fluidi. In particolare, nel laboratorio della Gatti Filtrazioni Lubrificanti viene utilizzato per analizzare i campioni di olio prelevati e identificare eventuali classi di contaminazione, potenzialmente pericolose per il corretto funzionamento dei macchinari.

La nostra dott.ssa Sara Gosio ci spiega di cosa si tratta…. Guarda il video!!

#Tecnologia #Scienza #Materiali #AnalisiChimica #Innovazione #Qualità #RicercaSviluppo #SpettrometroEmissioneOttica ... See MoreSee Less

Comment on Facebook